American Pattern has the capabilities to provide the perfect balance of the latest technology and industry-experienced professionals. From concept through completion, American Pattern & CNC Works will meet your prototype tooling requirements.

3D Sand Printing

American Pattern is capable of producing a sand casting mold for solid parts with a volume of more than 13 cubic feet, producing everything from engine cores to axle housings. This rapid casting technology can save you months, some cases years, in research and prototype development.

Prototype Urethane Injection Molding

ROOK Injection Machine blends parts A and B to produce urethane plastic parts.

No-Bake Sand Molding

American Pattern and CNC Works no bake molding shop offers the most up to date technology and resin systems running every day. We calibrate our mixers every week to ensure proper sand to chemical ratios to produce the proper tensile mold strengths. Our shop offers 3 no bake molding lines along with a single core blowing station. We also have off -line core making stations.

Testing and Metallurgical Reports

Depending on customers requirements for quality reports we will outsource to our appropriate suppliers for most all reports. Upon request for quote, we can provide the following:

- Metal certification identifying the cast metal composition and mechanical properties.

- Raw casting layout using 3D scanning or conventional CMM/balloon drawing reports.

- Soundness/Radiography reports-(X-ray) for ductile iron castings.

- CMM Machined casting reports.

We can also supply Level 4 PPAP reports upon request containing the Part Submission Warrant, Soundness Report, Layout report-raw and/or machined and Metal Certification report.

Custom Waterjet Parts

Using your design our ours American Pattern and CNC Works Inc. can assist you in creating unique and difficult parts qirh oue 120″ x 60″ capacity Flow waterjet. Get custom production parts made to order up to 8″ thick or multi part fixtures in a fraction of the time.

Storage

60,000 sq-ft of tooling storage available.

Coremaking

With our custom Tinker Omega, no-bake, core blow machine we can make cores from 2 lbs. to 60 lbs.

Casting Modeling and Layout

With our in-house design engineers, along with our Creaform HandySCAN, we have the ability to go from 2D prints to 3D models. We also have the ability reverse engineer existing castings and create new tooling.

Prototype Foundry Casting

American Pattern and CNC Works Inc. partners with local suppliers to provide manufacturers prototype sand mold castings in:

- Gray Iron

- Ductile Iron

- Aluminum

- All Steel Alloys

- Bronze

- Red Brass

- Austempered Ductile Iron

- High Silicon Molybdenum

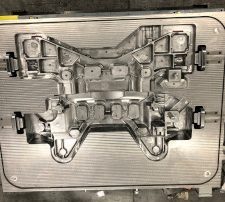

Production Pattern Tooling

Aided by state-of-the-art computer technology, we take maximum advantage of our equipment capabilities and customize them to satisfy your special circumstances. The result: Reliable, precision components, created and completed in our facilities, designed to equal or exceed your expectations.

Not every pattern shop can do what we do. With pattern plate sizes up to 120” x 60” and one of the largest capacity AWEA bridge mills in the country, we have the ability to produce larger patterns and tooling. And with the AWEA LP4021’s high speed machining, we can produce tooling 3-4 times faster, providing you with superior turn times.

Speed and precision – The American Pattern Difference.